It was a small entry in a 170-word story in Crain’s Detroit Business in December 2015.

The piece’s headline read “Energy Department awards $12.4 million to 4 Michigan projects” and the third-to-last paragraph said this: “Mackinac Technology Co. of Grand Rapids received $2.5 million to develop a single-pane, energy efficient window retrofit.”

Those 18 words belie the intense, painstaking and laborious work behind that window retrofit project, an undertaking with significant ties to Calvin, including Mackinac Technology Co. (Mackinac) founder and CEO John Slagter, a 1979 Calvin graduate, and a research team that includes professor of engineering emeritus Rich DeJong, current engineering professor Ren Tubergen, and a crew of five former and current students, including Daniel Wharton ’17 and Jonathan Sager ’17, who spent 10 weeks of hands-on work this past summer on the project.

Mackinac also works in close collaboration with Fraunhofer USA, a large R&D organization with an annual budget of more than $2 billion. Other Mackinac partners include the U.S. Army Corps of Engineers, the U.S. Air Force Academy and Oak Ridge National Laboratory. So, thanks to its relationship with Mackinac, Calvin is a key participant in an international project team of for-profit, nonprofit and government agencies.

A vexing problem

And the current project is an exciting one, says DeJong, dedicated to solving a vexing problem: energy losses from windows, especially in the wintertime and especially in older buildings, primarily from the 1970s, that were not built to prevent such energy loss.

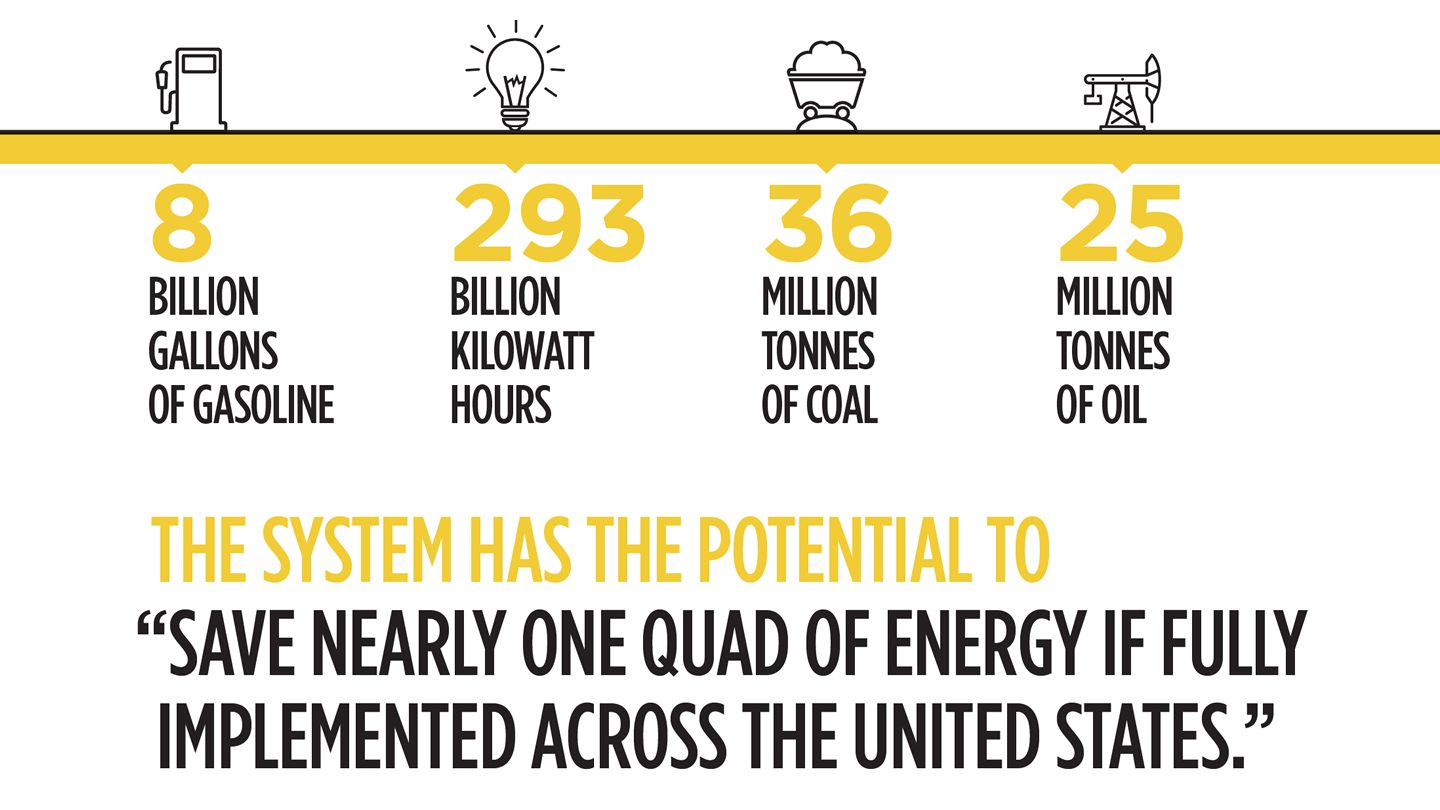

In awarding the grant to Slagter’s company, the Department of Energy’s Advanced Research Projects-Energy (ARPA-E) program noted that Mackinac’s approach to retrofitting windows with a low-cost insulation system has the potential to “save nearly one quad of energy if fully implemented across the United States.”

For the uninitiated, which DeJong admits would be many, one quad (short for quadrillion) is 10 to the 15th power of BTUs. Even that, DeJong adds, is hard to wrap one’s head around. He helpfully points out that a quad of energy would be 8 billion U.S. gallons of gasoline or 293 billion kilowatt hours or 36 million tonnes (metric tons) of coal or 25 million tonnes of oil.

So, says DeJong with a wry smile, “That’s a lot of energy.”

A valuable partnership

And while the stakes are high for Mackinac, so too is the learning for the Calvin students who have been part of the project since the beginning. Simply put, Tubergen says, the project gives Calvin students an opportunity to work with world-class scientists on a project that could have a huge impact on the world.

In so doing it lines up nicely, he adds, with the mission statement of the Calvin College engineering department, which notes that the program provides an education that is Christian, interdisciplinary, student-focused, practical, sustainable, global and innovative. Projects like the partnership with Mackinac, says Tubergen, check all the boxes.

Said partnership goes back almost five years, to the fall of 2012.

“John had heard of our experimental window setup in the Engineering Building,” says DeJong (the setup was donated by the Pella Corporation when the building was built), “and he approached me about joining him in a proposal to (Detroit-based utility company) DTE Energy for their E-Challenge program.”

To the delight of both Slagter and DeJong, that initial proposal was funded (“the infrastructure already in place at Calvin and the expertise of Dr. DeJong and other faculty at Calvin were key to preparing a strong proposal,” says Slagter), and thus began a partnership that continues today and has seen its fair share of both eureka moments and times of frustration.

Inching toward zero

This past summer’s two student interns, Wharton and Sager, found themselves experiencing both the highs and lows that such a long-term, hands-on project presents.

They spent the majority of the summer trying to figure out how to get the hot box (which is used to measure how well the treated windows guard against heat loss) down to zero degrees Fahrenheit.

The box has two compartments, a hot side and a cold side, separated by the window being tested. Its purpose is in strict, controlled laboratory conditions to simulate the heat loss on a cold day (0 F outside and 70 F inside).

The heat loss is determined by measuring the heat required to keep the hot side at 70 F while the cold side is cooled to 0 F with fans simulating an outdoor wind at 15 mph.

This summer’s challenge for the students was to achieve that temperature of 0 F on the cold side, and it was not an insubstantial one. In fact, previous students working on the project had gotten close, but not all the way. Wharton and Sager, building on the work of the prior interns, were able to reach the benchmark after two months of hard work, tweaks, starts and stops, postulating and testing hypotheses, failures and finally success.

Says Wharton: “We achieved it by adding insulation everywhere, mounting the fan motors outside the box, replacing the window insert holder, adding a freezer and countless other small adjustments to inch toward zero.”

Efforts rewarded

Despite the sometimes-frustrating nature of the project it was, Wharton, a senior engineering major from Fremont, Michigan, says, satisfying work.

“I got to do lots of construction, which I really enjoy. It was a perfect mix of hands-on building, CAD [computer-aided design] simulating and engineering calculations.”

Sager, a senior engineering major from Buffalo, New York, also enjoyed the hands-on nature of the project.

“Going into this position, I was under the impression that doing research would simply be me sitting at a desk taking data and plugging in some equations,” he says. “However, it was drastically different from that. Daniel and I were cutting wood and insulation, deconstructing and reconstructing fans and motors, designing air ducting systems within the box.”

“These students are performing high-level research work on par with what is being done at major research universities like MIT and the University of Michigan.” John Slagter

After all that work both students said the moment when the box finally got down to zero was a memorable one.

“When we both came in one morning to find that our box had finally gotten to a low enough temperature, I don’t think I have ever felt so much satisfaction from a job before,” recalls Sager.

And while sometimes discouraging to the students, the problem-solving nature of the project is also, they recognize, what makes it so valuable to their futures as engineers.

Slagter agrees: “These students are performing high-level research work on par with what is being done at major research universities like MIT and the University of Michigan.

“ARPA-E received 4,000 proposals and awarded only 41 contracts. This success and having the opportunity to work on an ARPA-E funded project is something these students can be very proud about.”

Calvin contributions

For his part, Slagter is proud of the students and grateful for their contributions and those of the many other Calvin folks who have played an important role in his work over the years.

Indeed, when Slagter began Mackinac in 2007, the late David DeHeer, a professor of biology, took Slagter under his wing, getting him access to research papers through Hekman Library and showing him how to write research grant proposals.

“His patient encouragement and support were invaluable,” Slagter says, “and here we are today with a major project funded by ARPA-E.”

Others at Calvin were equally valuable. Physics professor emeritus Howard Van Til reviewed early ideas and helped Slagter think through concepts, while current physics professors Matt Walhout and Steven Steenwyk and engineering professor Matthew Heun also all lent a hand and advice at various times.

Says Slagter: “I will always be grateful to these good people.”

DeJong and Tubergen are grateful to Slagter, noting that the work their students did this past summer is increasingly what employers expect engineering graduates to have as part of their portfolios. Top graduate schools also require some kind of undergraduate research experience (which this project fulfills).

And, says DeJong, projects such as this summer’s also meet part of the requirement for a sustainability designation on a student’s transcript, another edge when Calvin engineering grads hit the job market.

Students are paying attention. Sager came to Calvin because his brother was a chemical engineering major and, says Sager, “came back his first summer raving about Calvin College’s engineering program. So, I decided to see if it would live up to all the hype.”

There is no doubt, he says, that it has or that his summer 2016 experience has been an invaluable part of his Calvin journey.

“I was able to experience failing, the feeling like nothing will work,” he says, “and ultimately to see it working and to have that immense feeling of satisfaction. I know for both me and Daniel that will be valuable in whatever God calls us to do next.”

Phil de Haan is Calvin’s senior public relations specialist.